How to Keep Track of Inventory

Learn how to keep track of inventory effectively and enhance inventory visibility. Improve accuracy, minimize stockouts, and optimize warehouse efficiency.

Inventory management is a critical aspect of any business that deals with physical goods. It involves tracking the various items in a business's stock and ensuring that there are enough supplies to meet customer demand, while ensuring that there isn’t an unnecessary surplus. This delicate balance is achieved through a process known as inventory tracking, a process that can dramatically impact a business's efficiency, profitability, and overall success. This article will delve into what inventory tracking means, its importance, and practical methods to ensure accurate inventory management.

What does inventory tracking mean?

Inventory tracking, as the name already reveals, is a method of keeping tabs on every item in your inventory. It involves monitoring the journey of goods from the supplier, through the warehouse, and finally, into the hands of the customer, also referred to as “the last mile”. This could be through manual processes like checking off items in a ledger or automated systems like barcode scanning.

In a broader perspective, inventory tracking is part of inventory management, a discipline that deals with ordering, storing, and utilizing a company's inventory. But more than just a count of items, inventory tracking involves understanding the lifecycle of a product within the company - where it comes from, where it is stored, how it is sold, and when it needs to be restocked.

Inventory tracking is therefore important for businesses of all sizes. For instance, small businesses need it to manage their limited resources more effectively, while larger businesses need it to manage the complex logistical challenges that come with a larger scale operation.

Why it’s important to ensure full inventory visibility

Visibility into your inventory, referred to as inventory visibility, is crucial for efficient and profitable operations. Not only because it gives a clear picture of the goods available, their status, and location at any given point in time, but also because full inventory visibility can increase business performance in several ways.

Real-time inventory tracking contributes to better SCM

Supply Chain Management (SCM) refers to the coordination of all the processes involved in creating a product and getting it to the customer. Real-time inventory tracking provides live updates on inventory levels, helping businesses to make informed decisions promptly.

With real-time tracking, your business can respond faster to changes in demand, thereby reducing the risk of stockouts or overstocking. Also, it helps in maintaining optimal inventory levels, thereby reducing holding costs and increasing cash flow. Additionally, real-time data allows your business to communicate effectively with suppliers, enhancing their relationship and fostering better collaborations.

Inventory tracking enhances decision making

As another benefit, accurate inventory tracking provides critical data that can inform various business decisions. Firstly, it helps determine what products are selling well, which aren't, and when it's time to restock certain items. This information can inform purchasing decisions, marketing strategies, and even product development.

Inventory data can also help identify trends over time, such as seasonal changes in demand, and with this information in hand, your business can prepare for peak periods and avoid unnecessary expenses during slower times.

How to keep track of your warehouse inventory accurately

Implementing effective inventory tracking practices can make a significant difference in your warehouse operations. Here are some of the top methods to consider.

Key benefits of implementing an inventory management system

First and foremost, inventory management systems that employ robotics can bring about significant improvements in inventory tracking. These systems leverage robots to automate various tasks related to inventory management, such as moving goods around a warehouse, performing stock checks, and even packaging items for shipping.

Using robots instead of humans to manage inventory offers several advantages. Firstly, they can operate round the clock, increasing the warehouse’s overall productivity. Secondly, robots reduce the margin of error, ensuring more accurate inventory counts and tracking. Thirdly, they also improve safety within the warehouse by minimizing the need for human interaction with heavy goods or machinery.

The importance of efficient warehouse organization

An organized warehouse is the backbone of accurate inventory management. It allows for quicker, more efficient operations and can significantly reduce errors in inventory tracking. Here are some key tips for effective warehouse organization:

- Create a Logical Layout: The physical layout of your warehouse should facilitate easy access to items. Fast-moving items should be near the front to minimize travel time. Items that are often sold together should be stored near each other. Each area of the warehouse should be clearly marked, and all employees should understand the layout.

- Use Clear, Consistent Labeling: Every item, shelf, and area in your warehouse should be clearly labeled. This helps employees quickly locate items and reduces the chance of errors in picking and stocking. The labeling system should be consistent throughout the warehouse.

- Implement a Warehouse Management System (WMS): A WMS is a software application that helps control and manage daily operations in a warehouse. It can help optimize picking routes, manage space, and trigger reordering processes, making it easier to maintain an accurate inventory.

- Train Your Staff: Even the best systems and processes can fail if your staff don't know how to use them effectively. Regular training on inventory management practices, the use of inventory management software, and understanding the warehouse layout is essential.

- Maintain Cleanliness and Order: As basic as it may sound, a clean and tidy warehouse is simply easier to manage. It reduces the risk of items being lost, damaged, or misplaced. Regular cleaning schedules and an orderliness policy can go a long way in maintaining a well-organized warehouse!

By incorporating these strategies into your warehouse operations, you can significantly improve your inventory accuracy, operational efficiency, and ultimately, customer satisfaction. Remember, an organized warehouse is a productive warehouse. In relation, let’s look into how barcode scanners and automation can play a role in inventory tracking and productivity.

Utilize barcode scanning

Barcode scanning and Radio Frequency Identification (RFID) (less common) are two methods used to track inventory accurately. Both techniques involve attaching a unique identifier to each item in the warehouse.

A barcode scanner reads this identifier and updates the inventory management system each time an item is moved, sold, or returned. RFID tags serve a similar function but can be read from a distance and without direct line of sight, making them particularly useful in large warehouses.

Both these systems reduce human error and speed up the inventory tracking process, providing accurate and real-time updates.

.jpg)

What role does automation play in inventory tracking?

Automation plays a pivotal role in modern inventory tracking. With warehouse automation, your business can eliminate many of the manual tasks associated with inventory management, thereby reducing human error and improving efficiency.

Automated inventory management systems can track sales, update inventory records, generate purchase orders, and even forecast future demand based on historical data. This automation allows your business to keep up with the fast pace of the modern marketplace and make informed decisions quickly.

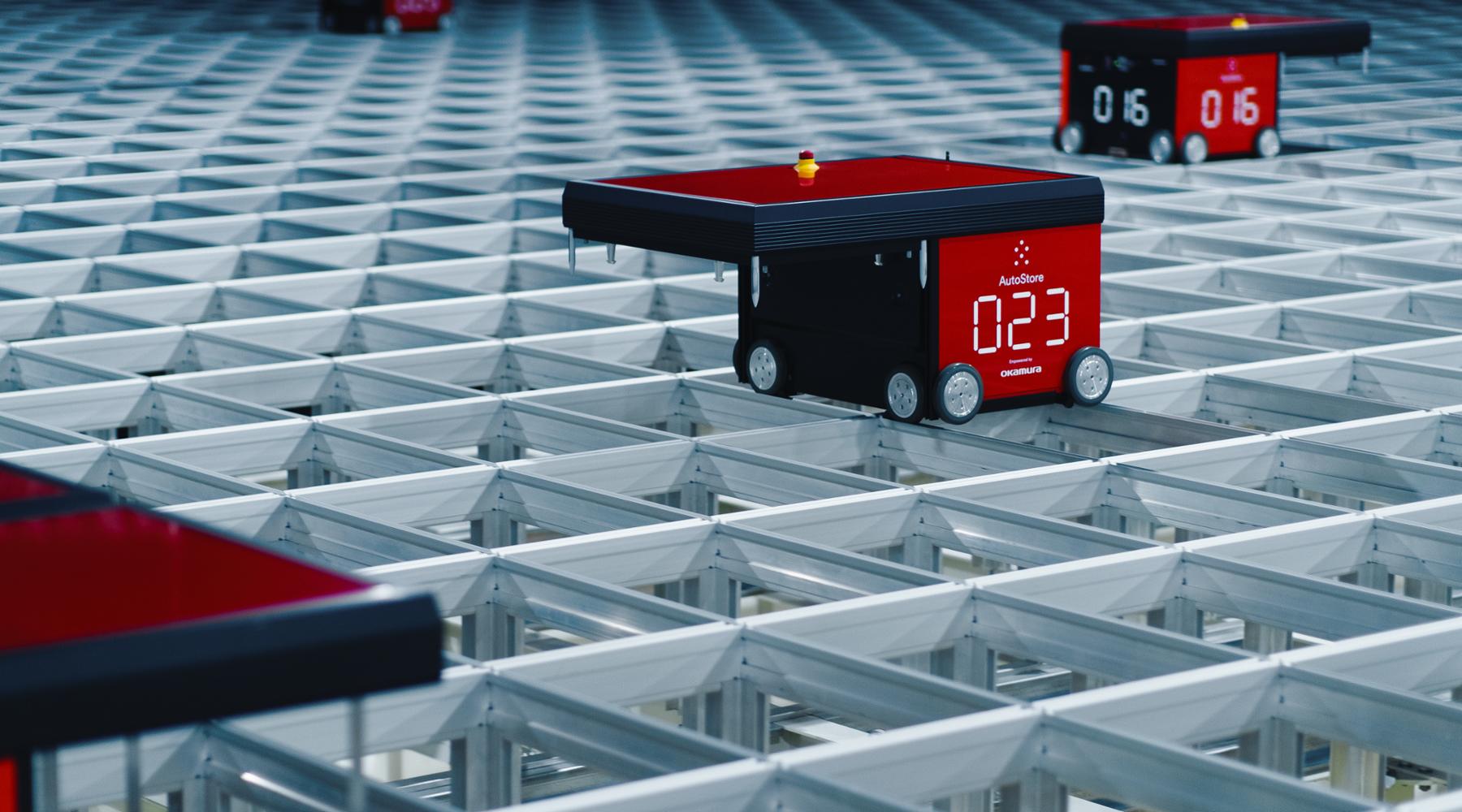

How AutoStore revolutionizes inventory tracking

In today's fast-paced logistics and warehousing sector, advancing beyond traditional inventory tracking methods is not just an option, but a necessity. AutoStore, a cutting-edge automated storage and retrieval system, revolutionizes the way businesses handle their inventory. This section explores the many ways in which AutoStore can elevate your inventory tracking processes to new heights of efficiency and accuracy.

1. Unparalleled Accuracy with Automation

AutoStore systems leverage advanced robotics and automation technology to manage inventory. The robots operate with precision, ensuring that every inventory Bin is accurately stored and retrieved. This automation minimizes human errors, significantly enhancing the accuracy of your inventory tracking.

2. Maximizing Space Efficiency

One of the standout features of AutoStore is its space optimization, recognized as the highest-density system in the automated storage and retrieval sector. The system uses a high-density storage cube that minimizes the warehouse footprint while maximizing storage capacity.

3. Scalability for Growing Needs

As businesses grow, so do their inventory needs. AutoStore's modular design allows for easy scalability. Whether it's increasing storage capacity or ramping up retrieval speed, the system can adapt to your growing inventory requirements without compromising on tracking efficiency.

4. Enhanced Security and Reduced Risk

With inventory securely stored in an automated system, the risk of theft, damage, or misplacement is significantly reduced. This security ensures that inventory tracking is not only accurate but also that the actual stock is well-protected.

5. Streamlining Order Fulfillment

The speed and accuracy of the AutoStore system directly impact order fulfillment. Quick retrieval times and precise inventory tracking mean that orders can be processed faster and more reliably, leading to improved customer satisfaction.

6. Data-Driven Insights

The integration with inventory management software allows for the collection and analysis of data. This data can provide valuable insights into inventory trends, helping in forecasting, identifying best-selling items, and understanding seasonal fluctuations in demand.

7. Cost-Effective Inventory Management

Finally, by automating many aspects of inventory management, AutoStore reduces the need for manual labor, leading to significant cost savings. This efficiency not only helps in reducing operational costs but also improves the overall bottom line.

In conclusion, AutoStore offers a sophisticated solution to the complex challenges of inventory tracking. By embracing this technology, businesses can ensure accuracy, efficiency, and scalability in their inventory management processes, positioning themselves for success in the competitive landscape of modern logistics and supply chain management.

How to minimize stockouts with accurate inventory tracking

Minimizing stockouts is crucial aspect of inventory tracking. Stockouts occur when a business runs out of a particular item, causing lost sales and potentially damaging customer relationships.

To avoid stockouts, your business need to have accurate demand forecasting methods in place. Demand forecasting uses historical sales data and market trends to predict future demand for each product. With this information, you can make informed decisions about when and how much to restock.

Another strategy is to have a safety stock - a small surplus of items to cover unexpected spikes in demand or supply chain disruptions. While this does incur additional storage costs, it can be a worthwhile investment to maintain customer satisfaction.

Conduct regular inventory audits to ensure accuracy

While automated systems and advanced tracking methods can significantly improve inventory accuracy, regular inventory audits still play a significant role in controlling your inventory. An inventory audit involves physically counting all the items in a warehouse and comparing the results with the records in the inventory management system.

The main benefit of audits is that they can help identify discrepancies between physical counts and system records, indicating issues like theft, damage, or data entry errors. Conducting regular audits ensures that the inventory management system reflects the actual state of the warehouse, allowing for accurate tracking and decision-making.

Conclusion

In conclusion, keeping track of inventory is not just about knowing how many items are in a warehouse. It's about understanding the lifecycle of each product, predicting future demand, and making informed decisions that can enhance the efficiency and profitability of your business.

By implementing effective tracking methods such as barcode scanning or RFID, leveraging automation, conducting regular audits, and utilizing strategies to minimize stockouts, your business can improve their inventory visibility and make more informed, data-driven decisions. Remember, effective inventory management is not a one-time task, but a continuous process of monitoring, adjusting, and improving!

FAQ

How do you keep track of inventory supplies?

You can keep track of inventory supplies by using inventory management software or systems. These systems will help you monitor stock levels in real time, set up automatic reordering points, and provide alerts when supplies are low. Regular physical audits are also essential to ensure the accuracy of the system data.

How do you keep track of inventory and expenses?

Inventory and expenses can be tracked using accounting or inventory management software. Such systems help you monitor the cost of goods sold, operational expenses, and inventory value. They can also generate reports that allow you to analyze patterns and trends over time. Linking your inventory data with your financial data can provide valuable insights into profitability and cost management.

What do you use to track inventory?

Several methods can be used to track inventory, depending on the size and needs of your business. Small businesses might use simple spreadsheet programs or manual ledgers. As a business grows, more sophisticated methods become necessary, like inventory management software, barcode scanners, RFID systems, or even automated robots for large-scale operations. The goal of these tools is to provide real-time, accurate data about stock levels and movement.